Final Project Proposal

Written on November 20th, 2022 by Petrina Chan

Final Project Propsal

Working Files

Concept

As I was thinking about this, I realized that I am going to be out of town for a whole week for Thanksgiving, which is a week when I will not be able to access machines or materials since I will be at home in Minnesota. My flight was booked a while ago, and I could not change it. Because of this, I am opting for a rather simple project that hopefully does not have a very lengthy physical fabrication process (e.g. laser cutting, 3d printing, assembly, etc). I will essentially have less than a week to physically make this project, so I don’t have much room for error.

My plan is to make a candle holder shaped like a great blue heron. The project will utilize:

- Rhino

- 3D printing

- Laser cutting

- Molding & casting

- Press fit parts

- Designing around stock parts

Context: I have a lot of random candles sitting around and I like birds

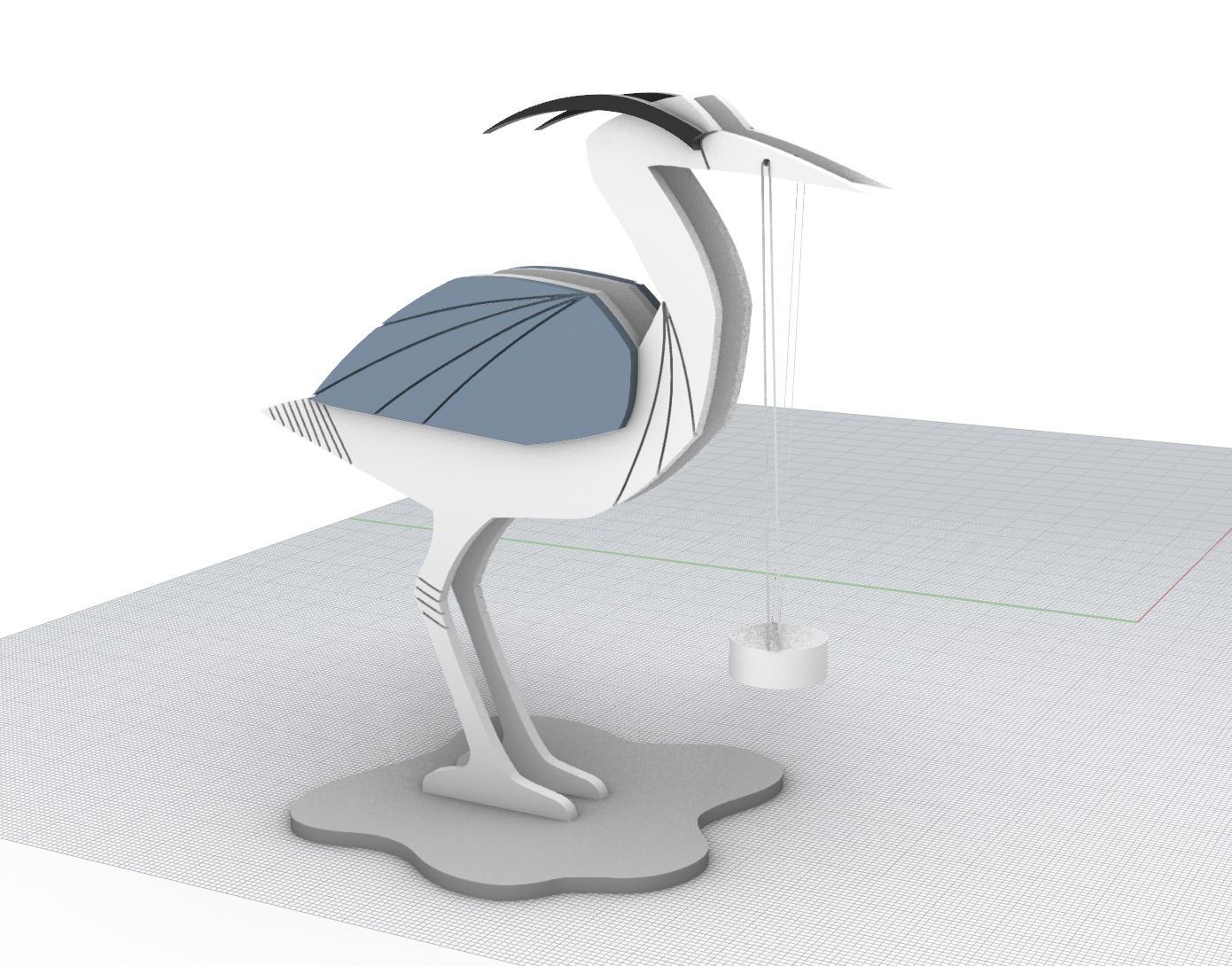

Here is what I hope the final product will look like. I envision him sitting on a coffee table, shelf, or window ledge:

Real heron for reference. Source

Real heron for reference. Source

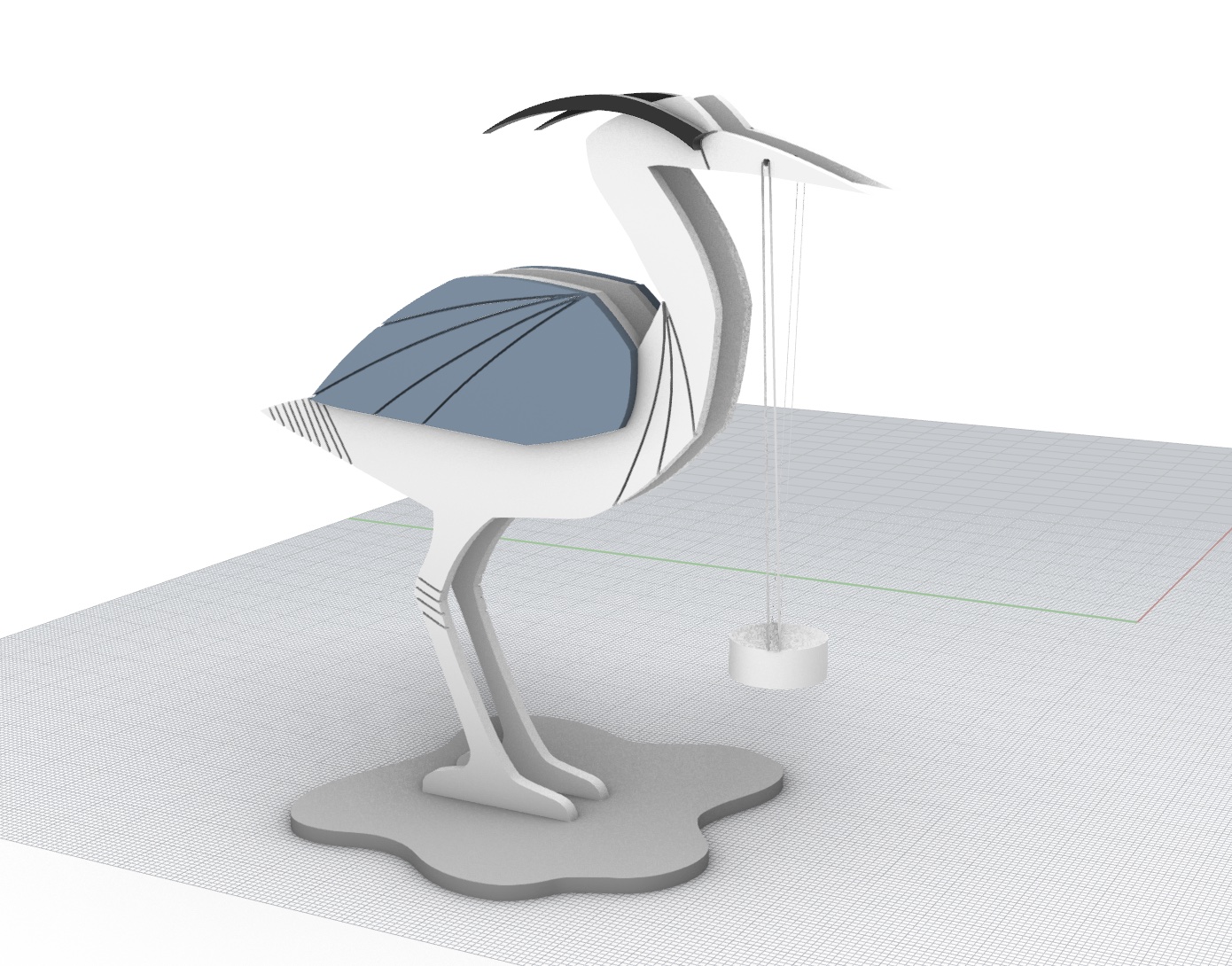

The main body would be made of laser cut frosted acrylic. The tufts of hair on the head would be 3D printed along with the wings. Both these printed components would be press fitted into the body via circular pegs into holes in the acrylic body. The two halves of the bird would just be mirrors of each other and joined by a similar press fit mechanic. While poking around online, I found this postfrom someone exploring press fit parts for round holes.

I am thinking of using the octagonal peg shape (bottom right) that they listed as their favorite.

The platform the bird is standing on will be made of casted plaster material and potentially lightly painted to have a rock-like texture (depending on if I think it will look good when I see everything together). I will create a candle holder for the candle based on an existing candle (likely an LED tea light so that the heat doesn’t affect the acrylic?). It will be suspended by wire strung through the beak hole and the candle holder.

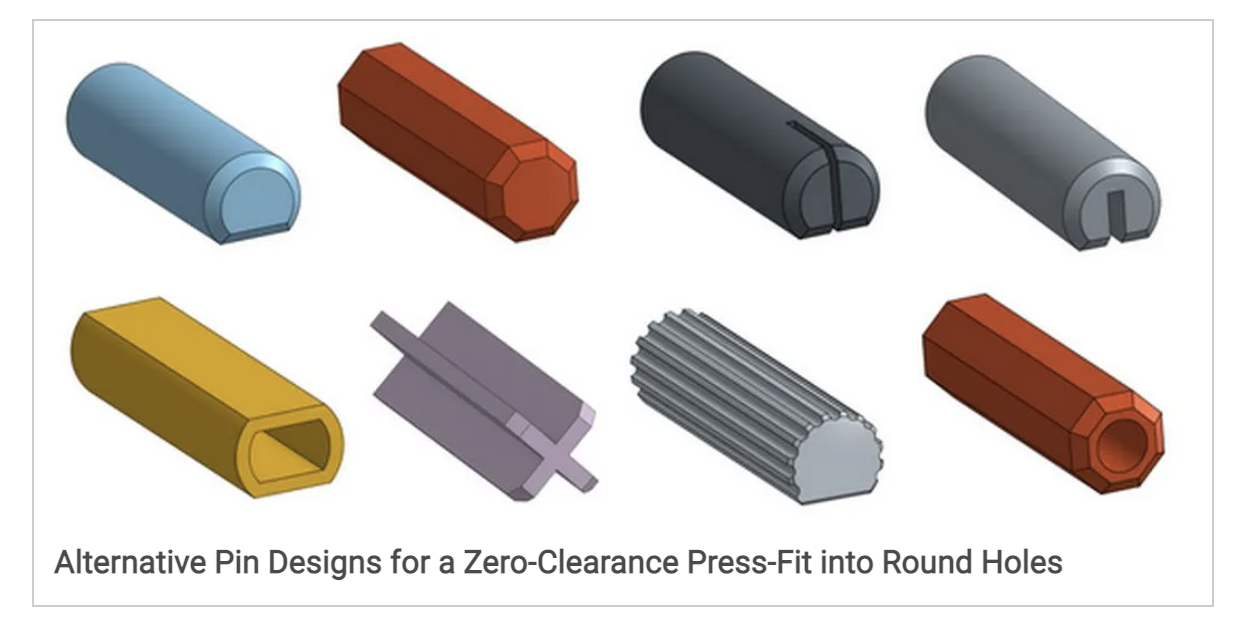

Here are the sketches and plans:

This was my initial pencil sketch of what I envisioned for the project

This was my initial pencil sketch of what I envisioned for the project

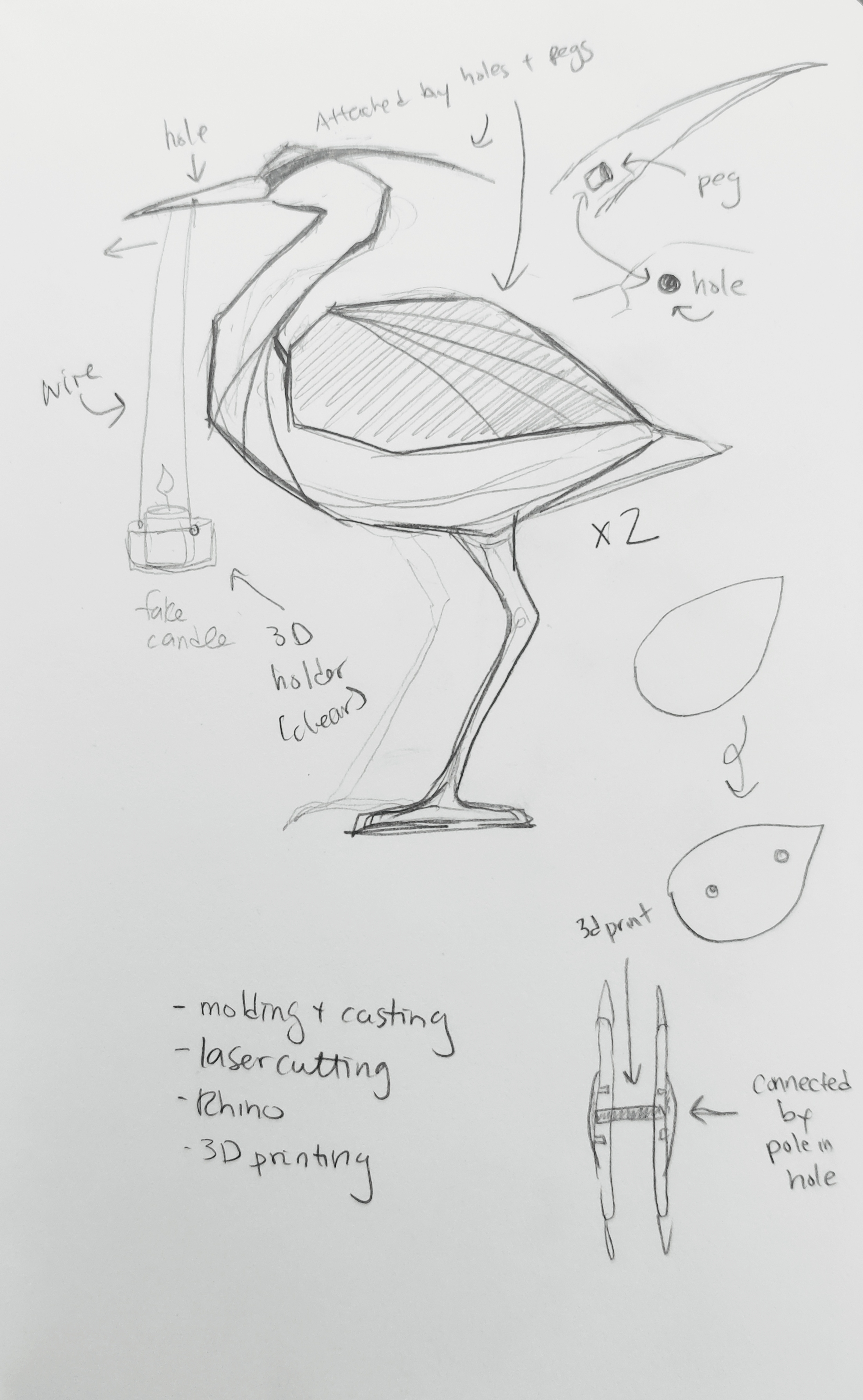

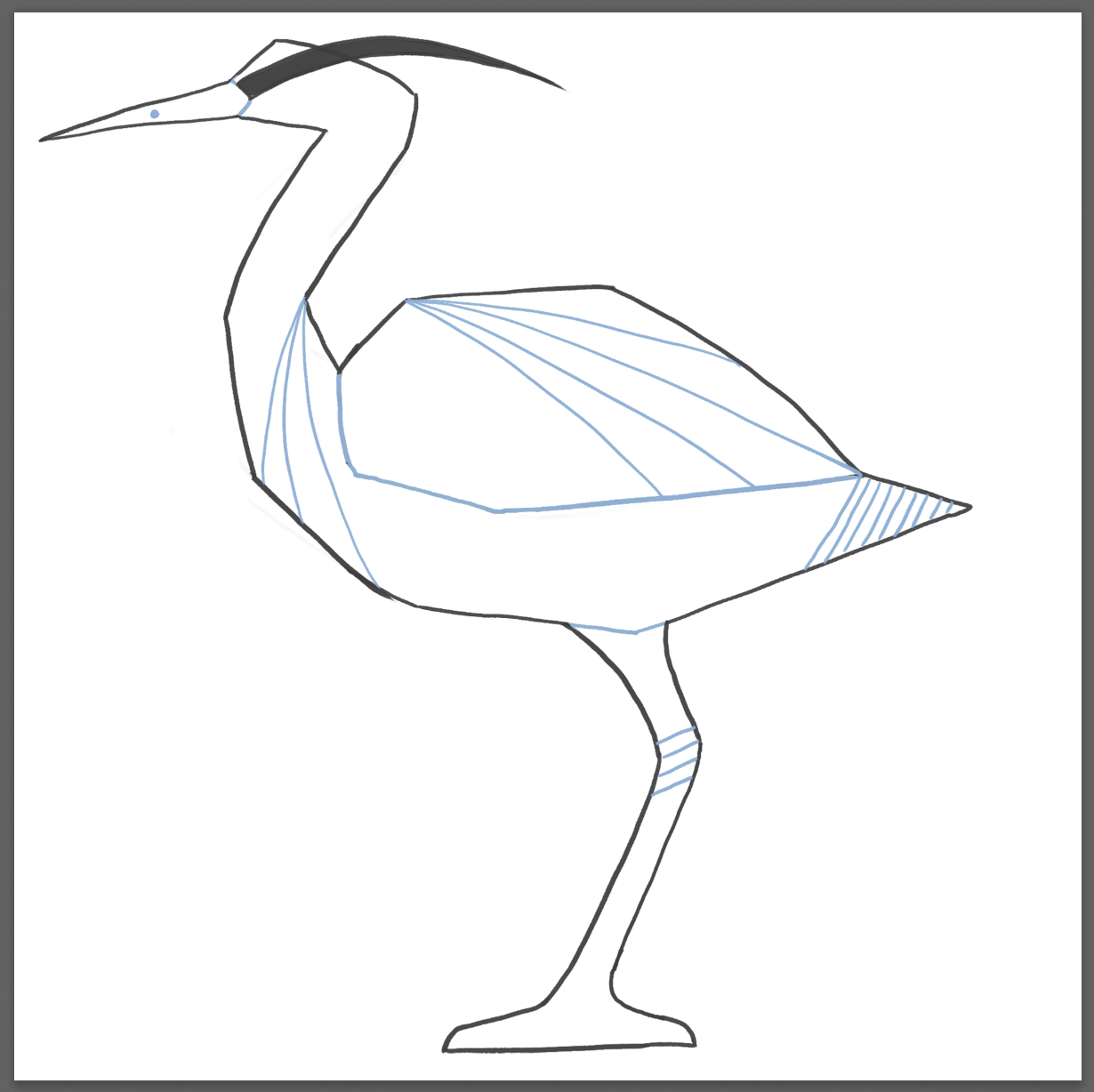

Next, I cleaned up the sketch in Photoshop. Blue lines indicate engravings or debossing in the 3D print.

Next, I cleaned up the sketch in Photoshop. Blue lines indicate engravings or debossing in the 3D print.

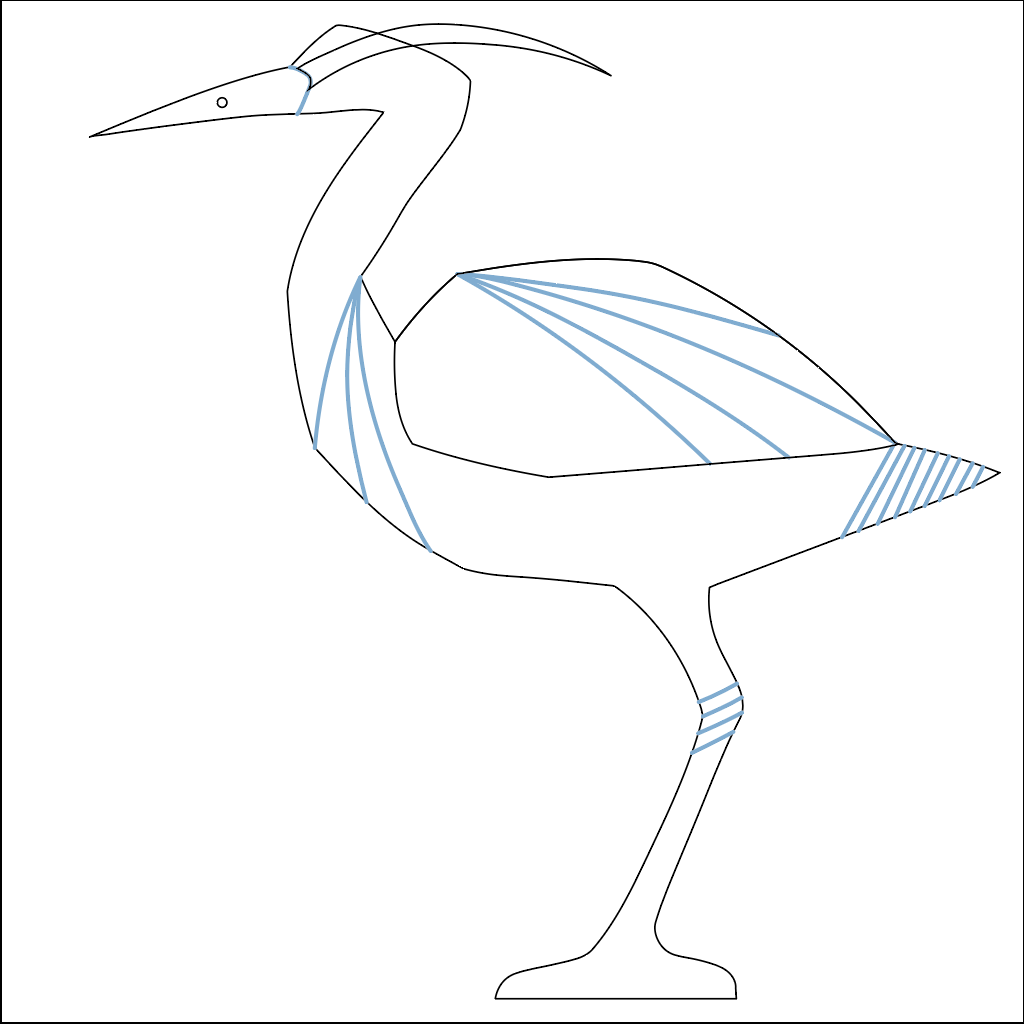

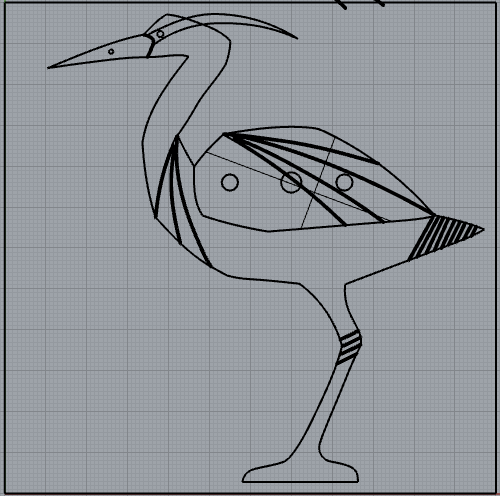

I then brought it into Illustrator to make the lines and curves both for Rhino and laser cutting. Strokes are made bigger here just so the lines are visibile in this image.

I then brought it into Illustrator to make the lines and curves both for Rhino and laser cutting. Strokes are made bigger here just so the lines are visibile in this image.

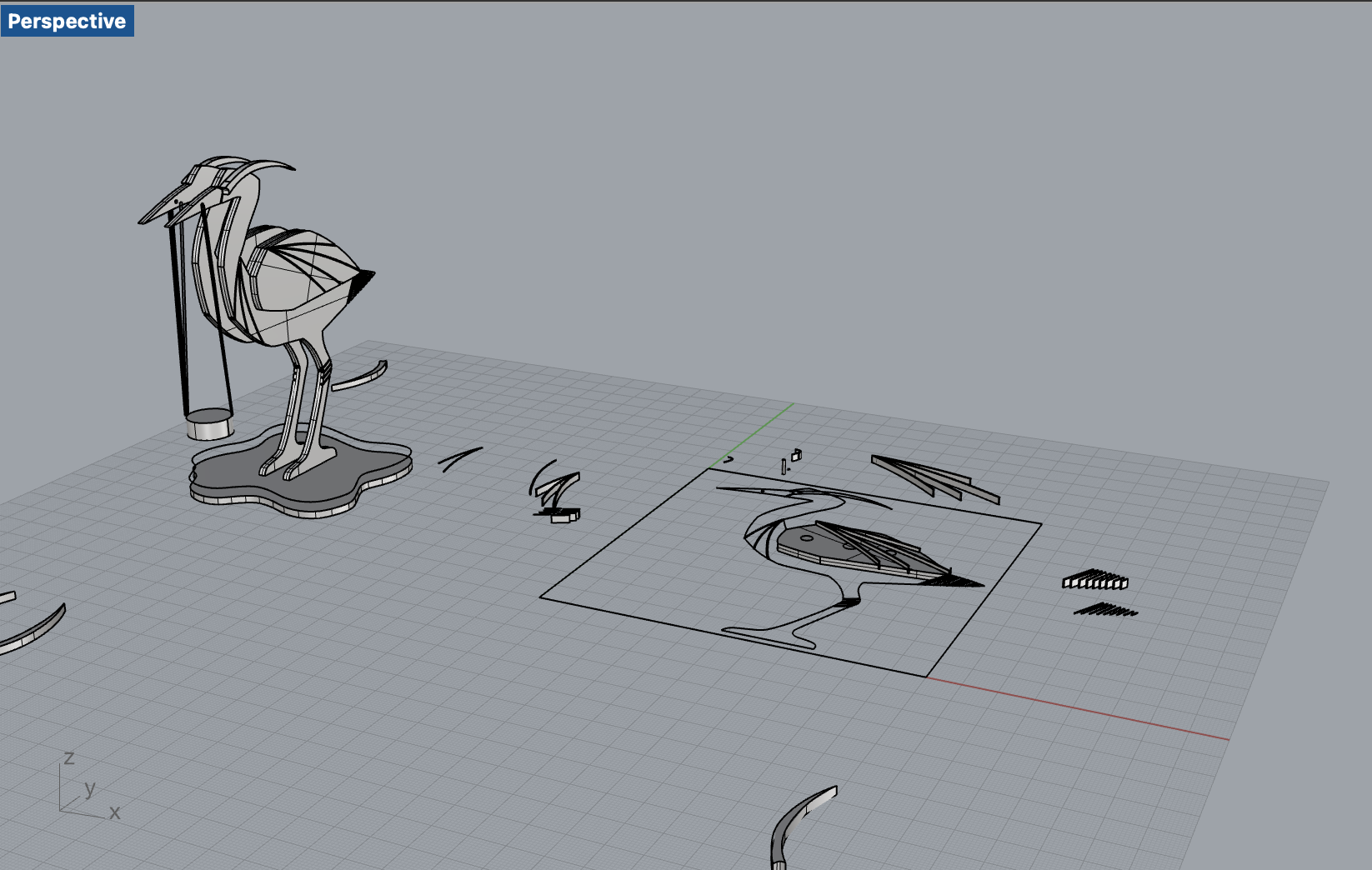

After importing into Rhino, I made sure all components and sizes would work and fit together as I hoped.

After importing into Rhino, I made sure all components and sizes would work and fit together as I hoped.

I’m currently working on getting all the components made and defined in Rhino! Will start cutting and printing when I get back in a week.

List of materials needed: Source // Acquired // Acquire by date

- 3x 1/4” thick 12x24” frosted acrylic sheets // Acquired

- 11(?) gauge wire // Blick or Pacific Hardware // Dec 4

- Black PLA filament // Acquired

- White PLA filament // Acquired

- 3D printer // Acquired

- Pliers // Acquired

- Sandpaper (100, 200, 600 grit) // Acquired

- Superglue // Acquired

- Oomoo // Acquired

- Perfect Cast // Acquired

- LED candle // Borrow from home // Nov 29

- Acrylic paint // Blick // Dec 2

- Paint brushes // Acquired

- Primer // Blick // Dec 2

Tasks & Timeline: Steps // Complete by date // Contingency plan

Since I return to Seattle on Nov 29, I have to wait until then to do anything non-digital. To be quite honest, I don’t have much room for contingency plans other than making parts with different methods. My project is realtively stripped down I feel like. This should be enough time to get everything made if I stick to it. In the case of any mishaps (things not fitting together, minor print issues), I will be able to troubleshoot and jerry rig on the fly (sanding parts for a fit, adding material for tigher fit).

- Initial plan & sketches // Done

- Create curves in Illustrator // Done

- Mock up model in Rhino // Done

- Measure candle // Nov 25

- Model wings and hair pieces // Nov 27

- Make model for platform mold // Nov 27

- Make model for dowel to attach halves // Nov 27

- 3D print platform mold // Dec 2

- 3D print wings and hair pieces // Dec 2

- 3D print attachment dowel // Dec 2

- Laser cut main body pieces // Dec 2 // If laser cutter out of commission: 3D print pieces (must be glued together)

- 3D print candle holder // Dec 2 // Option to use stock candle holder

- Cast platform // Dec 4 // If issues: can 3D print platform as well

- Paint platform and wings // Dec 4

- Assemble // Dec 5

Calendar view to come